Penyusun Berlapis Aliran Dengan Penukar Haba Binaan

Penerangan

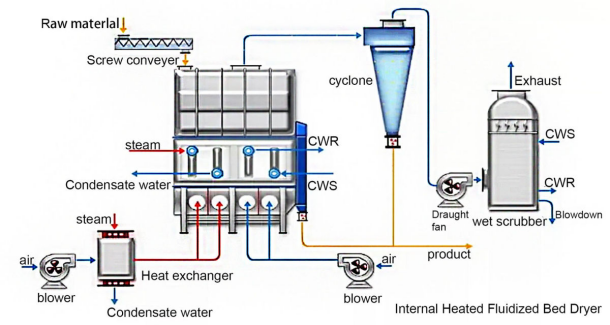

Pengering tempat tidur aliran terpansuh dalaman adalah teknologi pengeringan baru yang dibangunkan berdasarkan pengering tempat tidur aliran tradisional dengan pengeringan pemanasan tidak langsung.

Prinsip kerja

Pengering tempat tidur fluida dipanaskan dalaman dibahagikan kepada bahagian atas dan bawah tempat tidur, pelat taburan udara, port masukan dan keluaran, dll. Perbezaannya dengan pengering tempat tidur fluida biasa adalah terdapat pemenukaran haba dalaman yang diletakkan di bahagian pengecaman aliran dalam badan tempat tidur bawah, dan sumber haba bagi pemenukaran haba boleh menjadi steam atau minyak pemindah haba, dll. Kebanyakan haba disediakan oleh peranti pertukaran haba dalaman dengan kecekapan pertukaran haba yang tinggi, jadi udara panas terutamanya digunakan sebagai medium kuasa untuk memastikan pengecaman normal, dan kuantiti udara panas yang diperlukan telah berkurang secara ketara berbanding pengering tempat tidur fluida biasa.

Ciri-ciri

1. Kecekapan dalam menghemat tenaga adalah tinggi. Kebanyakan haba disediakan oleh penukar haba dalam katil dengan kecekapan lebih kurang 90%, udara panas digunakan terutamanya untuk memastikan pengaliran cecair normal, kuantiti udara panas jauh lebih sedikit berbanding yang diperlukan oleh pengering katil fluid konvensional; penggunaan kuasa dan kehilangan haba udara pembuangan dikurangkan, mengakibatkan kecekapan pengeringan yang lebih tinggi.

2. Kerana kelajuan aliran gas dalam sistem adalah lebih rendah berbanding pengering katil fluid konvensional, bahan yang dibawa oleh udara dari pengering katil fluid dikurangkan secara signifikan, beban sistem dedusting dikurangkan dan perlindungan alam sekitar ditingkatkan secara bersesuaian.

3. Penggunaan penyebar udara khas untuk mencegah bocornya bahan.

4. Mudah dipasang, mudah dioperasikan, murah untuk penyelenggaraan.

5. Penggabungan katil pengeringan dan penyejukan, ruang lantai kecil, pelaburan rendah.

Bahan yang Berkenaan

Asid adipic, abu soda, garam terpurnikan, sodium percarbonat, sodium sulfat anhidrat, kalium klorida, kalium nitrat, klorida amonium, nitrat amonium, sulfat amonium, kalsium klorida, kalsium hipoklorit, kalsium sulfat, tanah liat porselein butiran, baja kira-kira, sulfat besi, karbonat kalium, klorat kalium, fosfat kalium, tartrat kalium, lumpur, hidrogenkarbonat natrium, bromida natrium, klorat natrium, format natrium PVC, CPE, PC, dll.

Spesifikasi

Spesifikasi:

| TAIP | Kemampuan membuang air (kg/jam) | Kuasa terpasang (kW) | Tekanan kuap (MPa) | Ukuran (Panjang × Lebar × Tinggi) (mm) |

| GWLN5. 0 | 300~1200 | 40~80 | 0. 1~2. 0 | 4000×1500×5000 |

| GWLN8. 0 | 500~2000 | 60~120 | 0. 1~2. 0 | 7000×1500×6000 |

| GWLN10. 0 | 600~2500 | 80~160 | 0. 1~2. 0 | 7000×1800×7000 |

| GWLN20. 0 | 1200~5000 | 150~320 | 0. 1~2. 0 | 13000×1800×7000 |

| GWLN30. 0 | 1800~7000 | 250~450 | 0. 1~2. 0 | 15000×2000×7000 |

| GWLN45. 0 | 3000~11000 | 300~700 | 0. 1~2. 0 | 13000×4200×7000 |

| GWLN60. 0 | 4000~14000 | 450~900 | 0. 1~2. 0 | 15000×4200×7000 |

| GWLN70. 0 | 5000~16800 | 500~1100 | 0. 1~2. 0 | 15000×5000×7000 |

| GWLN80. 0 | 6000~19000 | 650~1300 | 0. 1~2. 0 | 20000×5000×7000 |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ