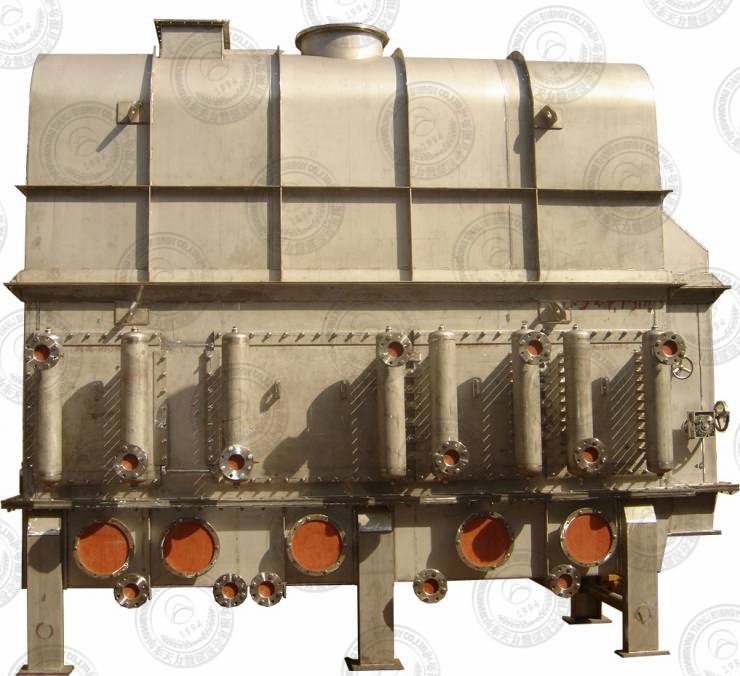

Adopting fluid bed dryer with built-in heat exchanger process, with the advantages of high drying efficiency and convenient maintenance. Tail gas treatment can be used according to the owner's production needs of dry and wet process technology to ensure that the emission standards.

Fluid bed dryer with built-in heat exchanger is a new drying technology developed on the basis of boiling fluid bed dryer drying and indirect heating drying. It will tube heat exchanger immersed in fluid dry materials, built-in heat exchanger through the heat (cold) medium, material dehydration (cooling) heat required by the built-in heat exchanger to provide, so as to meet the requirements of the material fluidization with a small air volume. Fluidizing medium mainly carries water and maintains the normal fluidization of bed particles. The drying (cooling) process is mainly built-in heat exchanger and two-phase flow of heat transfer and two-phase flow between the heat and mass transfer process.