Rotary Dryer

Description

Rotary dryer is a kind of drying equipment for processing large quantities of materials. It has characteristics of reliable operation, large operation flexibility, strong adaptability, large processing capacity, strong adaptability of materials, drying of various materials. It is widely used in building materials, metallurgy, chemical, cement industry to dry slag limestone, coal powder, slag, clay and other materials.

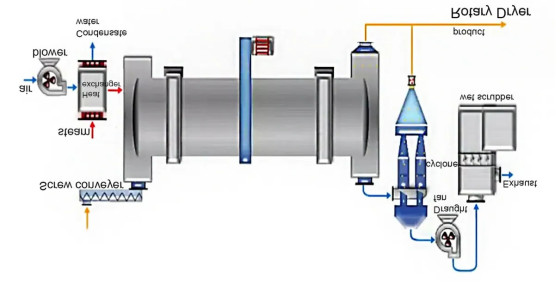

Working Principle

The rotary dryer is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring. The dryer is a cylinder that is slightly inclined from the horizontal direction. The material is added from the higher end,The high-temperature heat source and the material parallelly flow or counter-flow into the cylinder. As the cylinder rotates, the material runs to the lower end. The lifting board on the inner wall of the cylinder lifts up and drops down the material, so that the contact surface of the material and the air flow is increased to increase the drying rate and promote the advancement of the material. The dried product exits the dryer from the lower end.

Characteristics

1. Large drying capacity.

2. Continuous, steady operation.

3. Adjustable rotating speed fitting the requirements of different materials.

4. According to different material characteristic, it chooses different inner structure to meet drying requirement of the materials.

5. Effective prevention of the material against sticking on the wall; an ideal system for drying of material with high moisture content and viscosity.

Applicable Materials

Widely used in chemical, mining, metallurgy, agriculture, feed, fertilizer and other industrial fields. Such as ore, slag, coal, metal powder, diatomaceous earth, kaolin, starch residue, distiller's grains, dregs, soy sauce residue, fertilizer, potassium chloride, potassium sulfate, etc., sludge, aquatic product waste, food factory waste, phosphorus fertilizer sulfur Ammonium, light calcium carbonate, clay, lime slurry, ore mud, phosphate rock slag, aluminum plant red mud.

Specification

| Specification | Length(m) | Evaporative Capacity(kgH2O/h) | Temperature(℃) | Speed(r/min) | Slope(%) |

| HZ1200 | 10~14 | ~800 | 850℃ | 0.5~5 | 1.5~4 |

| HZ1500 | 12~16 | ~1500 | |||

| HZ1800 | 16~20 | ~2600 | |||

| HZ2000 | 18~22 | ~3600 | |||

| HZ2200 | 20~24 | ~5000 | |||

| HZ2400 | 22~26 | ~6500 | |||

| HZ2600 | 24~30 | ~8000 | |||

| HZ2800 | 26~32 | ~9000 | |||

| HZ3000 | 28~34 | ~10000 | |||

| HZ3200 | 30~36 | ~11500 | |||

| HZ3600 | 34~40 | ~14000 | |||

| HZ4000 | 38~44 | ~19000 | |||

| HZ4500 | 40~60 | ~25000 |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ