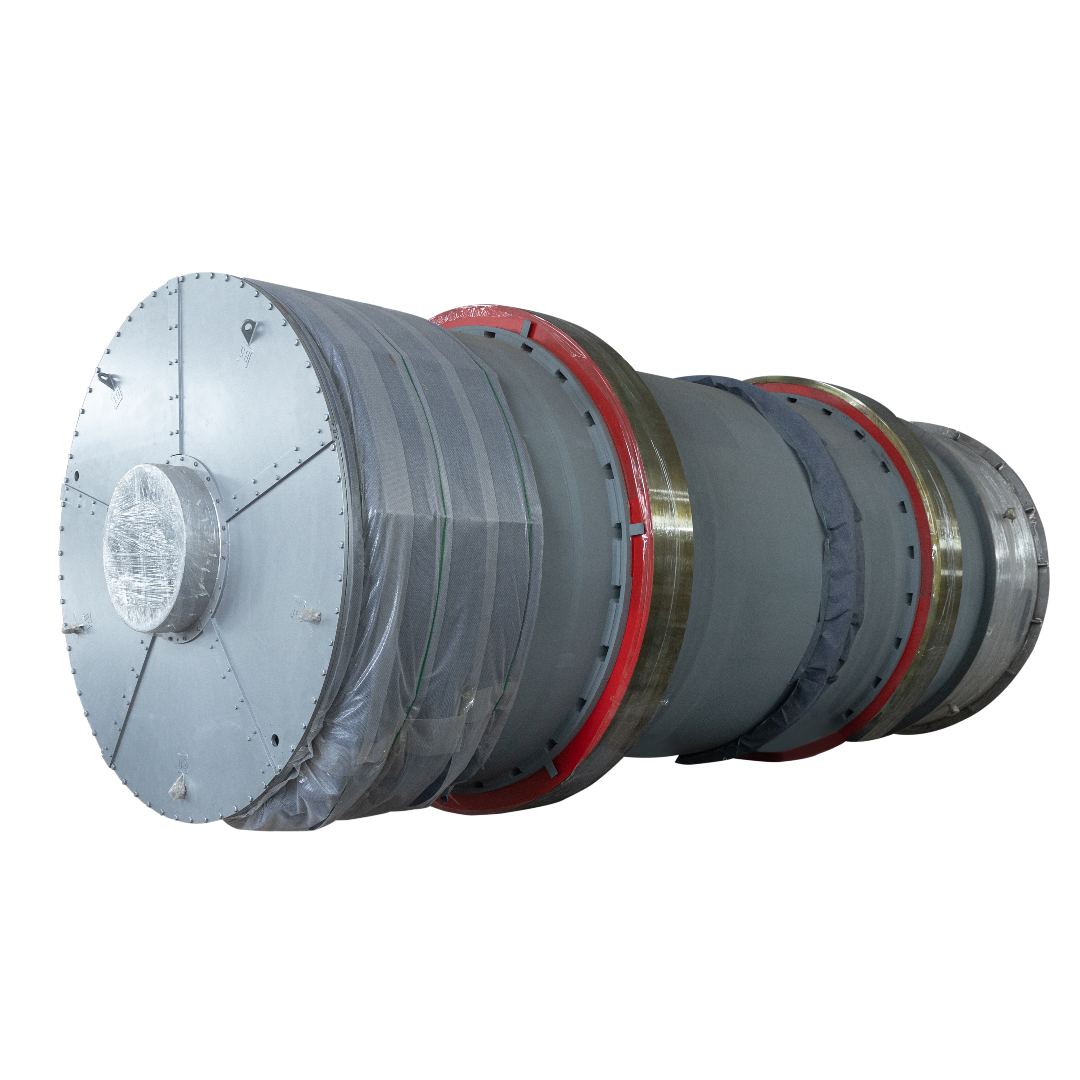

Steam Rotary Dryer

Description

Based on the structure of conventional rotary dryer, the steam rotary dryer is equipped with some steam heating tubes inside of the dryer. This dryer is used in drying of mineral powder, has the advantages of large processing capacity, fast drying speed and low energy consumption. The steam rotary dryer can reduce the production cost, is a drying device that can adapt to large flow of ore powder, reduce energy consumption and environmentally friendly.

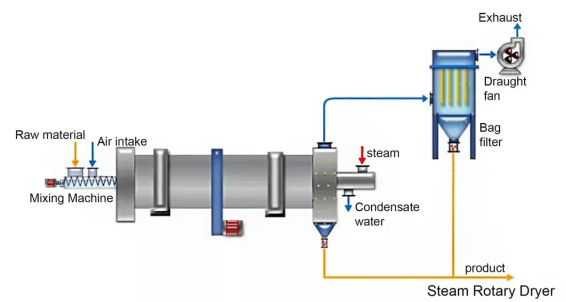

Working Principle

The steam rotary dryer is equipped with a steam heating pipe in the conventional rotary dryer. The heating pipe runs through the whole dryer and rotates with the cylinder. The material entering the rotary cylinder is lifted and stirred by the heating pipe in the rotating drum, and dried by the heat provided by the heating pipe.

The dried product is moved from the higher end to the lower end by the inclination of the dryer and discharged from the discharging port at the lower end. And the vaporized water is discharged under the action of the fan. For the organic solvent, a closed type steam rotary dryer can be used, and the organic solvent is recovered by circulating the inert gas to prevent explosion.

Characteristics

1. Large heat transfer area, high thermal efficiency.

2. The processing capacity is large, single machine can reach 200t / h.

3. The equipment has good sealing performance, suitable for the recovery of organic solvents.

4. The structure is simple, easy to operate, low maintenance cost.

5. Good sealing, no dust leakage, less environmental pollution.

Applicable Materials

Suitable for material drying and calcination using steam as heat source. Such as: polyethylene (PE), terephthalic acid (PTA), polyoxymethylene (POM), ABS resin, gypsum, copper fine powder, iron fine powder, coal powder, activated carbon, soda ash, coal slime, potassium carbonate and fluorite powder, etc.

Specification

| Specification | Length(m) | heat transfer surface(m2) | Speed (r/min) | Slope (%) |

| GZQ1200 | 9~14 | 90~140 | 0. 5~5 | 1. 5~3. 5 |

| GZQ1600 | 12~18 | 200~330 | ||

| GZQ1800 | 14~20 | 250~480 | ||

| GZQ2200 | 16~24 | 530~800 | ||

| GZQ2600 | 18~28 | 840~1300 | ||

| GZQ3000 | 24~30 | 1450~1800 | ||

| GZQ3600 | 30~40 | 2000~2600 | ||

| GZQ4000 | 35~45 | 2700~3000 | ||

| GZQ4200 | 40~50 | 3200~3500 |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

UR

UR

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK

UZ

UZ